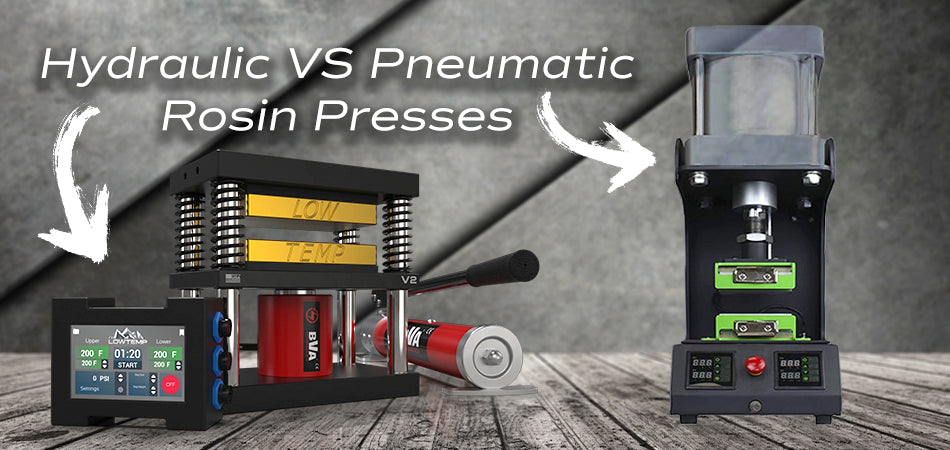

Hydraulic vs Pneumatic Rosin Press Comparison

Commercial-grade rosin presses come in two main varieties: hydraulic and pneumatic. Both hydraulic and pneumatic presses can be used to produce high-quality, marketable rosin.

The main difference between hydraulic and pneumatic rosin presses is that they create pressure via different mechanisms: Hydraulic presses create pressure with compressed fluid whereas pneumatic presses use compressed air.

The right kind of press for you will depend on your budget, space, and desired throughput.

How Pneumatic and Hydraulic Rosin Presses Work

Rosin presses all work in similar ways—whether you're working with a pneumatic or hydraulic press. They have two plates or platens that contain an electric heating element. The heat melts the trichome cuticles on dry flower, kief, dry sift, and bubble hash to release the resinous oil inside.

Once heated, the plates are pressed together using a pump (this can be pneumatic, hydraulic, manual, electric, or hybrid). The pressure, combined with heat, forces the cannabinoid and terpene-rich resin to flow out of the starting material onto parchment paper for collection. Learning how to use a rosin press is quite simple once you’ve got the right equipment.

Features of a Quality Rosin Press

In the early days, people made rosin with hair straighteners. Today, there are industrial rosin presses that offer the same core features (heated plates and pressure) with more force, greater precision, and far higher throughput.

Whether you opt for a hydraulic or pneumatic press, look for a rosin press with:

- Rectangular plates. The plates on your rosin press should be longer than they are wide. Our rosin presses come with plates measuring 3"x5" and 4"x7". These dimensions provide optimal pressure distribution and encourage the rosin to flow out quickly rather than staying on the plates and burning.

- Even heat distribution. You'll get the best results when heat is evenly distributed across each plate. Our LT3 Rosin Press Heat and Pressure Controller allows you to monitor the heat on each side of the plate via thermocouples to see whether your temps are uniform.

Are Hydraulic or Pneumatic Presses Better?

Both hydraulic and pneumatic presses have their advantages and disadvantages. We personally like hydraulic presses for two reasons:

- Hydraulics give you real time pressure feedback that allows you to feel the pressure release as rosin flows.

- Hydraulics give you the ability to scale with one operator using 5 presses running off a single pump, such as in our 5-Press Medusa System.

Hydraulic Press vs Pneumatic Press

To choose the best kind of press for your operation, it's important to understand how both types work as well as their distinct advantages and disadvantages.

How Hydraulic Presses Work

Hydraulic rosin presses use compressed fluid (generally hydraulic oil) to create pressure. The pressure is then applied with a pump, electric pump, or pneumatic over hydraulic pump. Because of the pressurized fluid, the operator doesn't need to be especially strong to apply pressure to the plates using a hydraulic pump.

Advantages of Hydraulic Presses

- Lower cost. Hydraulic presses generally cost less than pneumatic presses upfront because of their simpler design. When you purchase one of our rosin presses, you can choose between several different hydraulic pump options with different pressure application methods, including hand pumps, electric pumps operated off a button, and foot pedals.

- Lightweight. Hydraulic presses weigh far less than pneumatic presses.

- Quiet. Hydraulic presses are virtually silent unless you’re using an electric hydraulic pump. A quiet pump is an advantage if you're working in a tight space and can't house the pump in a separate room.

- More tactile feedback. The manual pressure application with hydraulic presses allows you to feel the pressure leaving the bag.

Disadvantages of Hydraulic Presses

- Manual operation. The main disadvantage of hydraulic presses is that they require manual operation. However, as noted earlier, this allows you to receive tactile feedback as you apply pressure.

How Pneumatic Presses Work

Pneumatic rosin presses generate pressure with compressed air. Because they work by manipulating pressurized air, pneumatic presses are also known as air press machines.

Advantages of Pneumatic Presses

- Can be automated. The main advantage of pneumatic presses is that they can be automated by programming the pressure ramping of the air compressor.

Disadvantages of Pneumatic Presses

- Heavy. Pneumatic rosin presses are much heavier and bulkier than hydraulic presses. They are best used for permanent set-ups rather than temporary ones.

- Noisy. The noise of the motor can be unpleasant for some people. To get around this, some extraction companies house their pneumatic pump in another room and connect it to the rosin press through the wall.

- Potential for dust contamination. Pneumatic presses have an air blowoff port that can blow dust particles into the air. These dust particles could potentially contaminate your hash.

- Larger upfront investment. Pneumatic rosin presses can cost two or three times as much as hydraulic presses. That's why it's important to calculate your potential daily throughput and income before purchasing a press. We offer a Rosin Profit Calculator to help you make informed decisions when purchasing solventless extraction equipment.

Cost-Effectiveness of Hydraulic vs Pneumatic Presses

Rosin presses generally cost in the low thousands for hydraulic and between $8,000 and $10,000 for pneumatic. Use our Rosin Profit Calculator to decide which type would make the most financial sense for your setup.

Alternative Types of Rosin Presses

We've covered hydraulic and pneumatic presses. However, they aren't the only types. These are three other common kinds of rosin presses on the market:

- Manual presses. Manual presses are operated purely with a hand crank. It takes physical strength to operate a purely manual press.

- Electric presses. Electric presses apply force using electricity rather than pressurized air or a pressurized fluid. They typically cost far more than other kinds of presses but allow for high precision and minimal human involvement.

-

Hybrid. Hybrid presses are generally hydraulic presses that can be customized with a hand, foot, electric, or pneumatic pump. This can be an advantage if you’re starting out small but plan to grow your operation in the future.

Choose Your Press Type With Lowtemp

At Lowtemp, we want people to be able to customize their rosin presses. That's why we've made our presses with open-source connections so you can pair them with any kind of pump.

When you buy a Lowtemp V2 Rosin Press, you can choose from several pump options we offer or even buy a $40-50 bottle jack if you're only pressing rosin as a hobby. Our pump options are:

- BVA Standard Compact Hand Pump. This pump comes with the hydraulics already assembled, bled, and tested. Our BVA Standard Compact Hand Pump has a 20-ton BVA cylinder, a compact aluminum pump, a hose, couplings, and a pressure gauge.

- BVA Premium Large Hand Pump. This pump is best for higher workloads. It provides more travel per stroke and has a longer handle for greater leverage.

- BVA Air Pump. This pump can be operated with a foot pedal or with hand pressure. It features a 20-ton hydraulic cylinder operated with an air compressor, and a pressure gauge. Please note that the air compressor must be purchased separately.

- BVA High Flow Premium Hand Pump. This pump has four times the travel per stroke compared to the Industry Standard P1000. It can be used with our single V2 rosin presses all the way up to our 4-Press Medusa System.

-

BVA Electric Pump. This hydraulic electric pump is operated by the press of a button and can go up to 10,000 psi. This pump is only available with our 5-Press Medusa System.

Customize Your Extraction Process

There are myriad options when it comes to building the perfect rosin press. We've designed our system so you can connect a range of pump types and customize everything from the plates to the cage.

The good news about the different kinds of pumps is that there are options for every price point. Experiment with hydraulic and pneumatic pumps using our LT3 controller to see which gives you the best results.